A na-ejikarị jig eme ihe n'ọnọdu (iji chọpụta ọnọdụ ziri ezi nke workpiece na ntinye), ngwaọrụ ndozi, ihe na-eduzi cutter (iji chọpụta ọnọdụ nke onye na-egbu osisi na workpiece ma ọ bụ ntuziaka onye na-ahụ maka ụzọ), ngwaọrụ nkerisi (nke mere na workpiece nwere ike mezue nhazi nke ọtụtụ ọdụ na abụọ nrụnye, gụnyere rotary na linear na-akpụ akpụ nkerisi ngwaọrụ), ejikọta element na fixture ahu (fixture base), etc.For example, ịgbado ọkụ jig, nnyocha jig, mgbakọ jig, igwe jig, na ihe ndị ọzọ, nke igwe jig bụ nkịtị, na-emekarị abbreviated dị ka jig.Mgbe nhazi workpieces na igwe ngwá ọrụ.Iji mee ka elu nke workpiece zute ihe achọrọ teknụzụ nke akụkụ, ụdị geometric na ịdị n'otu ọnọdụ nke ebe ndị ọzọ akọwapụtara na eserese ahụ, a ga-edobe workpiece, tinye ya na clamped tupu nhazi.

Enwere ike kewaa ụdị Jig n'ime: ① universal jig. Dị ka igwe vise, chuck, sucker, nkerisi isi na rotary table, wdg, nwere nnukwu universality.Ọ nwere ike ime mgbanwe nke ọma na mgbanwe nke nhazi usoro na nhazi ihe.Edebere ihe owuwu ya, akụkụ ya na nkọwapụta ya bụ serialized, ọtụtụ n'ime ha aghọọla ngwa ọkọlọtọ nke ngwaọrụ igwe.② Jig pụrụiche.Ihe ọrụ ahụ pụrụ iche ma lekwasịrị anya nke ukwuu.N'ozuzu, ọ na-mere site emeputa.Commonly, na-agụnye lathe jig,-egwe ọka igwe jig, egwu egwu anwụ (igwe ngwá ọrụ jig maka eduzi cutter ka akuakuzinwo ma ọ bụ reamer oghere na workpiece), na-agwụ ike anwụ (igwe ngwá ọrụ jig maka eduzi na-agwụ ike ngwá ọrụ). oghere na workpiece) Na soro jig (maka mobile fixture na akpaka akara nke jikọtara igwe ngwá ọrụ) ③ Agbanwe jig.A pụrụ iche jig nwere ike dochie ma ọ bụ gbanwee maka components. nkọwa na USES kwesịrị ekwesị maka nnwale mmepụta nke ọhụrụ ngwaahịa na onye iberibe, obere ogbe mmepụta na nwa oge aga-eme ugboro ugboro dochie anya ọhụrụ ngwaahịa.Na mgbakwunye na vice, chuck, nkerisi isi na rotary table, e nwekwara a nkịtị aka cutter.N'ikwu okwu n'ozuzu, mgbe okwu cutter na jig pụtara n'otu oge, ọtụtụ n'ime jigs na-ezo aka na onye na-eji aka.

lathe jig

A na-akpọ ngwaọrụ jib eji arụ ọrụ n'ime, n'èzí na n'elu nke workpieces na lathe.

Igwe eji atụ ihe nchikota atọ

A na-eji ya na igwe nha na nkwado modular , ngwaọrụ ntụaka iji nweta ndozi na-agbanwe agbanwe nke workpiece n'okpuru test.The ngwaọrụ nwere ike hazie na-akpaghị aka na-akwado workpiece na melite na-akparaghị ókè ntụaka maka workpiece nhazi.Advanced pụrụ iche software, nwere ike ozugbo. site na geometric data nke workpiece, n'ime sekọnd ole na ole iji mepụta workpiece clamping usoro.

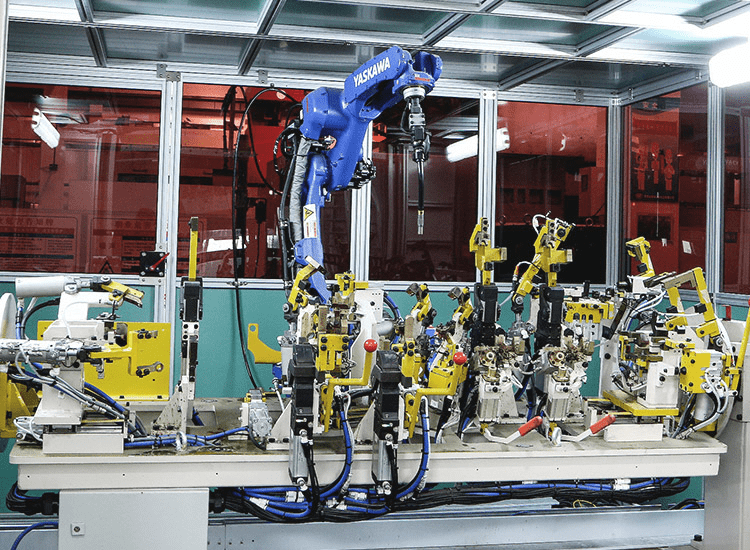

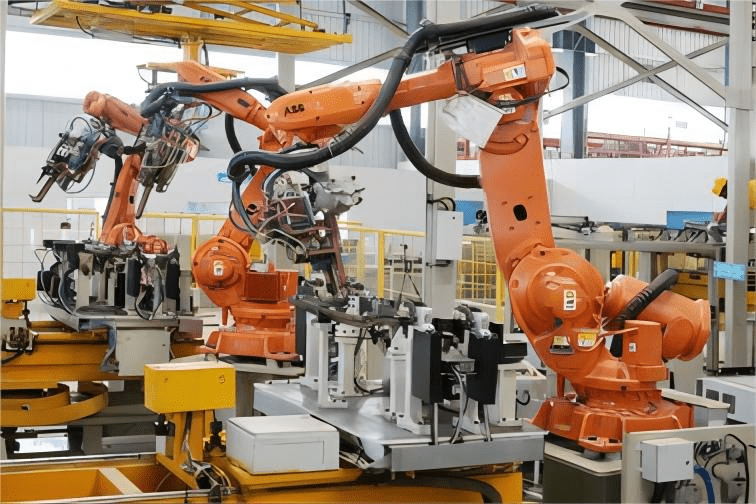

Igwe eji arụ ọrụ robot

A na-etinye ha niile na robots ụlọ ọrụ ma jiri ya na akụrụngwa akpaaka nke ụlọ ọrụ, nke bụ otu n'ime teknụzụ ọhụrụ nke akụrụngwa akụrụngwa nke ụlọ ọrụ ọgbara ọhụrụ. A na-ejikarị arụkọ ọrụ na robots eme ihe na mmepụta ụlọ ọrụ ọgbara ọhụrụ.Ihe a na-ejikarị eme ihe bụ ịkwanye na ibutu ngwá ọrụ igwe, nchịkọta workpiece, ịgbado ọkụ, egweri na ụlọ ọrụ ndị ọzọ na-akpaghị aka.

Igwe igwe igwe

A na-etinye ihe niile na tebụl egwe ọka, na igwe table nri ije ije. Ọ bụ tumadi mejupụtara n'ọnọdu ngwaọrụ, clamping ngwaọrụ, ihe clamping ngwaọrụ, jikọọ na cutter element.Na-egwe ọka, ike ọnwụ bụ nnukwu, na ọnwụ ike. na-adịte aka na ịma jijiji dị ukwuu. Ya mere, ike nkedo nke igwe igwe igwe dị ukwuu, na ike na ike nke ngwaọrụ jig dị elu.

Jig na-ebu pedestal

Iji hụ na mmepụta nke mmepụta ihe na-emepụta ihe na-eme ka ọkpụkpụ na-emepụta ihe na-eme ka ọ dịkwuo mma, na mgbakwunye na iji ngwá ọrụ igwe na ngwá ọrụ ndị ọzọ, a ga-eji ọnụ ọgụgụ dị ukwuu nke nkà na ụzụ na-emepụta ihe. Ihe enyemaka ndị metụtara ya. Ihe eji eme ihe eji eme ihe bụ ngwá ọrụ mmepụta nke a na-eji eme ihe n'ụzọ pụrụ iche na-ekwe nkwa ịdị mma nke ngwaahịa ndị na-ebu pedestal.Ọ nwere ike ime ka usoro mmepụta ihe dị mfe karị. ọnọdụ na ụkpụrụ imewe.Ya mere, e nwere ụdị dị iche iche na ụdị nke axle njide fixture, ma na nke ukwu na style.It nwere ike iji mee ka n'ụzọ ziri ezi na-ekpebi ndị ikwu ọnọdụ nke workpiece. na-emewanyewanyewanye, nke mere na mmegharị ahụ a chọrọ na nhazi nke workpiece nwere ike mezue. ihe ntinye nke na-ebu pedestal na-arụ ọrụ dị oke mkpa na usoro mmepụta ihe, ya mere ọ dị ezigbo mkpa ịbịaru ihe osise ihe eji eme ihe.

Oge nzipu: Jan-06-2023

.png)

.png)