Onye na-emepụta ihe na ụlọ ọrụ mmepụta ihe kacha mma na China

Mmepe ụlọ ọrụ

- Na 2011, TTM tọrọ ntọala na ShenZhen.

- Na 2012, Ịkwaga na DongGuan;Mmekọrịta mmekọrịta na Magna International Inc.

- Na 2013 Ewebata ihe elu equipments.

- Na 2016, ewebata akụrụngwa CMM buru ibu na akụrụngwa 5 axis CNC;Ejikọtara ya na OEM Ford Completed Porsche, Lamborghini na Tesla CF oru.

- Na 2017, Ịga na ebe osisi ugbu a;A mụbara CNC site na 8 ruo 17 sets.E hiwere Top Talent Automotive Fixtures & Jigs Co.Ltd

- Na 2018, jikọrọ aka na LEVDEO automotive wee mechaa ahịrị mmepụta akpaaka.E webatara 4-axis dị elu CNC, ngụkọta Qty nke CNC ruru 21.

- Na 2019, Dongguan Hong Xing Tool & Die Manufacturer Co., Ltd e guzobere.(Otu nkwụsị ọrụ) Na-arụkọ ọrụ na Tesla Shanghai na Sodecia Germany.Wuru ụlọ nyocha R&D ọhụrụ maka akpaaka.

- Na 2020, jikọrọ aka na OEM ISUZU na SA; Emechara RG06 One-Stop Service.

- Na 2021, Na-aga n'ihu na nkwenye dị mma iji mepụta ụlọ ọrụ klaasị ụwa.

- Na 2022, TTM Group ụlọ ọrụ tọrọ ntọala na Dongguan City, New CNC 4 axis * 5 sets, New Press * 630 tọn, Hexagon Absolute Arm.

- N'afọ 2023, TTM na-ewu ụlọ ọrụ ọhụrụ maka ịlele ngwa ngwa na azụmaahịa ịgbado ọkụ;na-agbakwunye otu 2000T pịa.

Ilele ihe ndozi & Welding Jigs Factory (Mkpokọta mpaghara: 9000m²)

Ngwa Stamping & Dies na Machined Factory (Ngụkọta mpaghara: 16000m²)

Nkọwa ngwaahịa

| Aha ngwaahịa | Ihe ndozi ịgbado ọkụ |

| Ngwa | Automotive CCB, Front End, WS Spring Link, Front Bumper wdg. |

| Ụdị ịgbado ọkụ | Ntụpọ ịgbado ọkụ, Arc ịgbado ọkụ, (CNC/Assembly) Pụrụ ịgbado ọkụ ihe ndozi |

| Mpempe Ngwakọta Pneumatic | SMC, FESTO, TUENKERS, CKD, njide akwụkwọ ntuziaka |

| Akara akụrụngwa akụrụngwa | OMRON, Mitsubishi, Siemens, Balluff |

| Ihe (Mgbochi, Ntụtụ ebe) | 45# Steel, ọla kọpa, igwe anaghị agba nchara |

| Ụzọ ọrụ | Robot ịgbado ọkụ, akwụkwọ ntuziaka, ịgbado ọkụ igwe pụrụ iche |

| Ụzọ njikwa | Njikwa ikuku (Pneumatic Control Valve), Njikwa eletriki (Solenoid Valve), Akwụkwọ ntuziaka, Ọ dịghị valvụ solenoid achọrọ Nye njikọ mgba ọkụ |

| Ụzọ mmachi | Pneumatic, akwụkwọ ntuziaka |

| Ụzọ Nkwukọrịta na Welding Cell | EtherCAT, PROFINET, CC-LINK |

| Igbe mgbasa ozi mgbasa ozi | Ụzọ eriri igbe eletriki, ụdị oghere ngwa ngwa, ụdị agwaetiti Solenoid valvụ |

| Ụdị ntọala Welding Fixture | Edobere n'ala, Positioner/Flip Tye |

| Ụzọ ọkpọkọ | Otu oyi akwa tube, ọkụ retardant tube, ọla kọpa / igwe anaghị agba nchara tube |

| Ọgwụgwọ Elu Nrụgide | Eserese, Eserese+Oxidization ojii, Mkpuchi Zinc, Ntụ ntụ ntụ |

| Etiti oge | 2-4 izu maka imewe na nyocha nyocha; 10-12 izu maka n'ichepụta mgbe imewe nkwenye 7-10 ụbọchị ọrụ maka mbupu ikuku; Izu 4-5 maka ịṅụ mmiri n'oké osimiri |

| Ndụ anwụ | Dabere na ikike mmepụta nke ndị ahịa |

| Inye mkpuchi dị mma | Nyocha CMM Jiri sample nwalee Ọpụpụ n'ịntanetị Ọgbakọ Weebụ vidiyo n'ịntanetị Zụrụ-apụ Ịdozi nsogbu ịzụta-apụ |

| ngwugwu | Igbe osisi maka ihe atụ; Igbe osisi ma ọ bụ pallet maka ihe ndozi; |

Ụgbọalaihe mgbado ọkụbụ ngwaọrụ dị oke mkpa n'ime usoro nrụpụta ụgbọ ala.Emebere ihe ndozi ndị a pụrụ iche iji hụ na nhazi na nhazi nke akụrụngwa dị iche iche, na-eme ka ịgbado ọkụ chassis, akụkụ ahụ na akụkụ ndị ọzọ dị oke egwu.Na nlebanya zuru oke nke a, anyị ga-enyocha akụkụ ndị bụ isi nke ngwa ịgbado ọkụ ụgbọ ala, gụnyere mkpa ha, nleba anya imewe, nrụpụta, njikwa mma, yana ọrụ ha na ụlọ ọrụ ụgbọ ala.1. Mkpa ihe mgbado ọkụ ụgbọ ala:

Ngwa ịgbado ọkụ akpaaka na-arụ ọrụ dị mkpa n'ichepụta ụgbọ ala n'ihi ọtụtụ ihe kpatara ya: nkenke: Ha na-ahụ maka nhazi nke akụrụngwa, na-eduga na welds na-agbanwe agbanwe na nke ziri ezi.Nke a dị oke mkpa maka nhazi nhazi na nchekwa nke ụgbọ ala.

Ịrụ ọrụ: Ngwunye ịgbado ọkụ na-eme ka usoro mgbakọ ahụ dị ngwa, na-ebelata oge mmepụta na ụgwọ ọrụ.Nkwa mma: Site na ijide akụkụ na ọnọdụ ziri ezi, ihe ndozi na-ebelata ohere nke njehie na ntụpọ na ngwaahịa ikpeazụ.Nkwenye: Ihe ndozi na-enye nsonaazụ na-agbanwe agbanwe, n'agbanyeghị ọkwa nka onye ọrụ, nke dị mkpa maka inweta ogo ụgbọ ala.2. Echiche Nhazi: Ịmepụta ngwa ịgbado ọkụ ụgbọ ala bụ usoro dị mgbagwoju anya nke na-agụnye nlezianya na-echebara ihe dị iche iche echiche: Ụdị ụgbọ ala: Nhazi nke ihe eji eme ihe ga-adaba na kpọmkwem ihe mere na ihe nlereanya nke ụgbọ a na-emepụta.Nke a na-achọ nghọta miri emi nke chọrọ mgbakọ ụgbọ ala.Ndokwa akụkụ: Ihe nrụnye ahụ ga-edobe nke ọma akụkụ ụgbọ ala dị iche iche, dị ka akụkụ ahụ, akụkụ chassis, na akụkụ etiti.Nke a gụnyere kpọmkwem ebe ebe, usoro mkpọchi, na ihe nkwado.Nkwekọrịta na Ndozi: Ndị injinia ga-atụlerịrị nnabata siri ike yana ihe achọrọ iji hụ na ihe mejupụtara ya dabara nke ọma.

Nhọrọ ihe: Nhọrọ nke ihe maka nrụnye dị oke mkpa.Ọ kwesịrị ịdịte aka, na-eguzogide okpomọkụ, na nke siri ike iguzogide usoro ịgbado ọkụ.Ergonomics: Ekwesịrị ịmebe ihe ndozi maka ịdị mfe iji yana nchekwa onye ọrụ.Nke a gụnyere echiche maka ịnweta, visibiliti, na ergonomics n'oge ọrụ ịgbado ọkụ.3. Ihe eji eme ihe:

Ịmepụta ngwa ịgbado ọkụ ụgbọ ala gụnyere ọtụtụ usoro:

CAD Design: Ndị na-emepụta ihe na-emepụta ụdị 3D CAD zuru ezu nke ihe nrụnye, na-akọwapụta ọnọdụ, nghazi, na ihe mgbochi maka mpaghara ọ bụla.Nhọrọ ihe: Dabere na nkọwa nhazi, a na-ahọrọ ihe ndị kwesịrị ekwesị, mgbe mgbe ígwè ma ọ bụ aluminom, maka ihe owuwu ihe.Nrụpụta akụrụngwa: akụrụngwa n'otu n'otu, gụnyere ihe nkwado, clamps, na ihe ndokwa, ka ejiri CNC machining na usoro ndị ọzọ pụrụ iche arụpụtara ya.Welding na Mgbakọ: Ndị na-ahụ maka welders na ndị ọrụ nka na-achịkọta ihe ndị ahụ, na-ahụ na ha dabara ọnụ nke ọma na nke ọma.Nnwale: Ngosipụta ahụ na-enweta nnwale siri ike iji hụ na ọ dabara n'usoro na nnabata achọrọ maka ịgbado ọkụ ziri ezi.Nke a gụnyere nleba anya nke akụrụngwa ụgbọ ala.Nhazi: A na-ahazi ihe nrụnye ahụ iji hụ na ọ ka nọ n'usoro zuru oke ma na-ejigide iguzosi ike n'ezi ihe nhazi ya.4. Njikwa Ogo: Ịkwado ụkpụrụ dị elu n'oge usoro ihe eji eme ihe dị mkpa: Nleba anya: A na-eme nyocha mgbe niile iji chọpụta izi ezi, ịdịte aka, na arụmọrụ nke ihe nrụnye.

Nlele nnabata: A na-eme nha ziri ezi na nlele nnabata iji gosi na ihe nrụnye ahụ ruru ụkpụrụ achọrọ.

Nkwenye nkwekọ: A na-enyocha ihe ndozi iji hụ na ha na-edobe nhazi na nhazi nke ọma maka mgbakọ.5. Ọrụ na Ụlọ Ọrụ Na-ahụ Maka Ngwá Ọrụ: Ngwá ọrụ ịgbado ọkụ na-arụ ọrụ bụ ihe dị mkpa na usoro mmepụta ụgbọ ala: Chassis Welding: Fixtures na-eme ka nhazi nke ọma nke chassis components, gụnyere akụkụ etiti na ihe nkwụsịtụ.Mgbado ọkụ nke ahụ: Ha na-ejide akụkụ ahụ, dị ka ọnụ ụzọ, mkpuchi, na ihe mgbochi, n'ọnọdụ ziri ezi maka ịgbado ọkụ, na-atụnye ụtụ n'izizi ezi n'ezi ihe nke ụgbọ ala ahụ.Seam Welding: A na-eji ihe ndozi eme ihe na ịgbado ọkụ nke seams, nkwonkwo, na njikọ iji mepụta njikọ siri ike na ntụkwasị obi.

Automation Welding: N'ọtụtụ ọnọdụ, a na-ejikọta ihe nrụnye ịgbado ọkụ na mkpụrụ ndụ ịgbado ọkụ nke robot maka mmepụta akpaaka, na-emewanye arụmọrụ na nkwụsi ike.6. Nhazi maka ndị na-emepụta ụgbọ ala: Ndị na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emepụta ihe na-emekarị ka ọ bụrụ ọkachamara n'ịmepụta ihe eji eme ihe na-eme ka ọ bụrụ mkpa pụrụ iche nke ndị na-emepụta ụgbọala.Emebere ihe nrụnye ndị a iji zute ụkpụrụ ụlọ ọrụ akọwapụtara na ihe achọrọ, yana enwere ike ịmegharị ha maka ụdị ụgbọ ala dị iche iche n'ime ahịrị ngwaahịa nke onye nrụpụta.N'ikpeazụ, ngwa ịgbado ọkụ ụgbọ ala bụ akụkụ dị oke mkpa nke usoro nrụpụta ụgbọ ala.

Ngwọta(Ọrụ Ngwọta Turnkey)

Sistemụ Mgbakọ Ọcha:

1, ahịrị ịgbado ọkụ n'ahụ ụgbọ ala zuru oke

2, Naanị otu onyeIgwe ịgbado ọkụ

3,Ihe ndozi ịgbado ọkụ na Jigs:

Ọnụ ego nke CCB ASSYIhe ndozi ịgbado ọkụ, Floor Pan ASSY Welding Fixture, Wheelhouse ASSY Welding Fixture, AB Ring ASSY AB Welding Fixture, Seat ASSY Welding Fixture, Front Seat Cross Member Welding Fixture, Front End ASSY Welding Fixture, Dash Panel ASSY Welding Fixture, Cowling ASSY Weld Welding Fixture emeputa, imewe ụlọ ọrụ na factory.

ISO Management System maka Welding Fixture

Anyị Welding Fixture Team

Uru Anyị

Ahụmahụ 1.Rich na nrụpụta akpaaka na njikwa ụlọ ọrụ.

2.One Stop Service maka stamping ngwá ọrụ, ịlele nkwụnye, welding fixtures na cell iji nweta oge na ego ịzọpụta, nkwurịta okwu mma, na-ebuli ahịa ahịa.

3.Professional engineering otu iji mechaa GD & T n'etiti otu akụkụ na mgbakọ mpaghara.

4.Turnkey Ngwọta Ọrụ-Stamping Ngwá Ọrụ, Nyochaa Fixture, Welding Fixtures and Cells with one team.

5.Strong ike na mba oru nkwado na mmekorita imekọ ihe ọnụ.

6.Big ikike: Nyochaa Fixture, 1500 sets / year; Welding Fixture and Cells, 400-600 sets / year;Ngwa stampụ, 200-300 set / afọ.

Anyị nwere ihe karịrị ndị ọrụ 352, 80% n'ime ha bụ ndị injinia dị elu.Ngwá ọrụ nkewa: 130 ọrụ, Welding fixture nkewa: 60 ọrụ, ịlele fixture nkewa:162 ọrụ, Anyị nwere ọkachamara ahịa & oru ngo otu, ogologo oge ọrụ esenidụt oru ngo, si RFQ ka mmepụta, Mbupu, mgbe-ahịa, anyị otu nwere ike ijikwa nsogbu niile maka ndị ahịa anyị na Chinese, Bekee na German Language.

Ahụmahụ nke nnukwu ọrụ sel nke ịgbado ọkụ na ihe mgbado ọkụ

| Isi ihe ndozi ịgbado ọkụ (2019-2021) | |||||

| Ihe | Nkọwa | Ụdị | Aha oru ngo | Qty(Nhazi) | Afọ |

| 1 | Ọnụ ego nke CCB WF | Arc Welding | VW MEB31 | 60 | 2019-2021 |

| 2 | Ọnụ ego nke CCB WF | Arc Welding | VW MEB41 | 10 | 2020 |

| 3 | Ọnụ ego nke CCB WF | Arc Welding | VW 316 | 4 | 2020 |

| 4 | Ọnụ ego nke CCB WF | Arc Welding | Ụlọ ọrụ Ford T6 | 8 | 2021 |

| 5 | Ọnụ ego nke CCB WF | Arc Welding | ISUZU RG06 | 3 | 2020 |

| 6 | Ọnụ ego nke CCB WF | Arc Welding | Bcar, BSUV | 6 | 2020 |

| 7 | Ọnụ ego nke CCB WF | Arc Welding | Bcar, BCAR | 7 | 2020 |

| 8 | Ala Pan WF | Sopt Welding | SK326/0RU_K Karoq RU | 15 | 2019 |

| VW316/5RU_K Tarek RU (19003) | |||||

| 9 | WS Spring njikọ WF | Arc Welding | WL/WS | 4 | 2019 |

| 10 | Crossmember Brackets WF | Arc Welding | WL/WS | 12 | 2019-2021 |

| 11 | N'ihu Bumper WF | Arc Welding | VW281 | 14 | 2019 |

| 12 | Ọnụ ego WF | Arc Welding | ISUSU RG06 | 18 | 2019 |

| 13 | SL ASY na MBR na EXT ASY | Spot na Arc Welding | Ford P703 | 25 | 2019-2021 |

| 14 | CCB WF na cell arụrụ arụ | Arc Welding | ISUSU RG06 | 6 | 2020 |

| 15 | Ihu oche Cross Onye otu WF | Sopt Welding | Volkswagen AG MEB316 (20001) | 4 | 2020 |

| 16 | Ulo ala Pan WF na Grippers | Sopt Welding | AUDI/PORSCHE PPE 41(19017 Oge 1) | 18 | 2020 |

| 17 | Ụlọ Wheel WF na Grippers | Arc Welding | Ford BX755 (19018) | 6 | 2020 |

| 18 | AB Ring WF na Grippers | Arc Welding | Ford BX755 (19018) | 14 | 2020 |

| 19 | Dash Panel WF na Grippers | Sopt Welding | South Africa Ford T6 (17028-1) | 10 | 2020 |

| 20 | Cowl WF na Grippers | Ebe ịgbado ọkụ | South Africa Ford T6 (17028-3) | 6 | 2020 |

| 21 | Front End WF na Grippers | Spot na Arc Welding | South Africa Ford T6 (17025) | 10 | 2020 |

| 22 | Rocker WF na Grippers | Ebe ịgbado ọkụ | South Africa Ford T6 (19029) | 8 | 2020 |

| 23 | Ulo ala Pan WF na Grippers | Sopt Welding | AUDI/PORSCHE PPE 41(19017 Oge 2) | 63 | 2021 |

| 24 | Ihe mkpuchi azụ na chassis WF | Arc Welding | Ford P703&J73 | 36 | 2020-2021 |

| Isi ihe ndozi ịgbado ọkụ (2022) | |||||

| Ihe | Nkọwa | Ụdị | Aha oru ngo | Qty(Nhazi) | Afọ |

| 25 | Mgbakwunye ọwa etiti WF | Sopt Welding | Vinfast VF36 | 8 | 2022 |

| 26 | Ulo ala Pan WF na Grippers | Sopt Welding | AUDI/PORSCHE PPE 41(19017 Oge 3&4) | 39 | 2022 |

| 27 | Ala Pan WF | Sopt Welding na amụma ịgbado ọkụ | Ford P703 PHEV | 29 | 2022 |

| 28 | Ulo ala Pan WF na Grippers | Sopt Welding | Porsche E4 Floor Pan (21050) | 16 | 2022 |

| 29 | Ọwara ala WF | Laser akara | Ọwara ala VW (21008) | 2 | 2022 |

| 30 | oche ASSY WF na Ngwá Ọrụ | Arc Welding | BYD oche ASSY | 40 | 2022 |

| 31 | Ala Pan WF | Spot na Arc Welding | Ndozigharị Ford | 24 | 2022 |

| 32 | Ọnụ ego nke CCB WF | Arc Welding | VW Cyclone CCB (21037) | 10 | 2022 |

| 33 | Ọnụ ego nke CCB WF | Arc Welding | VW MQB37 (22022) | 16 | 2022 |

| 34 | A&B-Pillar WF | Ebe ịgbado ọkụ | Gestamp GS2203 | 8 | 2022 |

| 35 | Robot Cell Base | NA | VW Cyclone | 4 | 2022 |

Ebe nrụpụta ihe ndozi ịgbado ọkụ

Anyị nwere ike wuo ụdị ọ bụla dị iche iche nha ịgbado ọkụ gụnyere nnukwu nha ka anyị nwere nnukwu igwe CNC.N'iji ngwá ọrụ dị iche iche dị iche iche dị ka igwe igwe, igwe ihe, igwe na-egbutu waya na igwe na-egwupụta ihe, anyị nwere ike ịchịkwa usoro nhazi nke ọma na nke ọma.

Usoro 25 nke CNC nwere ọrụ mgbanwe abụọ

1 Set nke 3-Axis CNC 3000*2000*1500

1 Set nke 3-Axis CNC 3000*2300*900

1 Set nke 3-Axis CNC 4000*2400*900

1 Set nke 3-Axis CNC 4000*2400*1000

1 Set nke 3-Axis CNC 6000*3000*1200

4 Set nke 3-Axis CNC 800*500*530

9 Set nke 3-Axis CNC 900*600*600

5 Set nke 3-Axis CNC 1100*800*500

1 Set nke 3-Axis CNC 1300*700*650

1 Set nke 3-Axis CNC 2500*1100*800

5 Axis CNC - igwe

4 Axis CNC - igwe

Welding Fixture Assembly Center

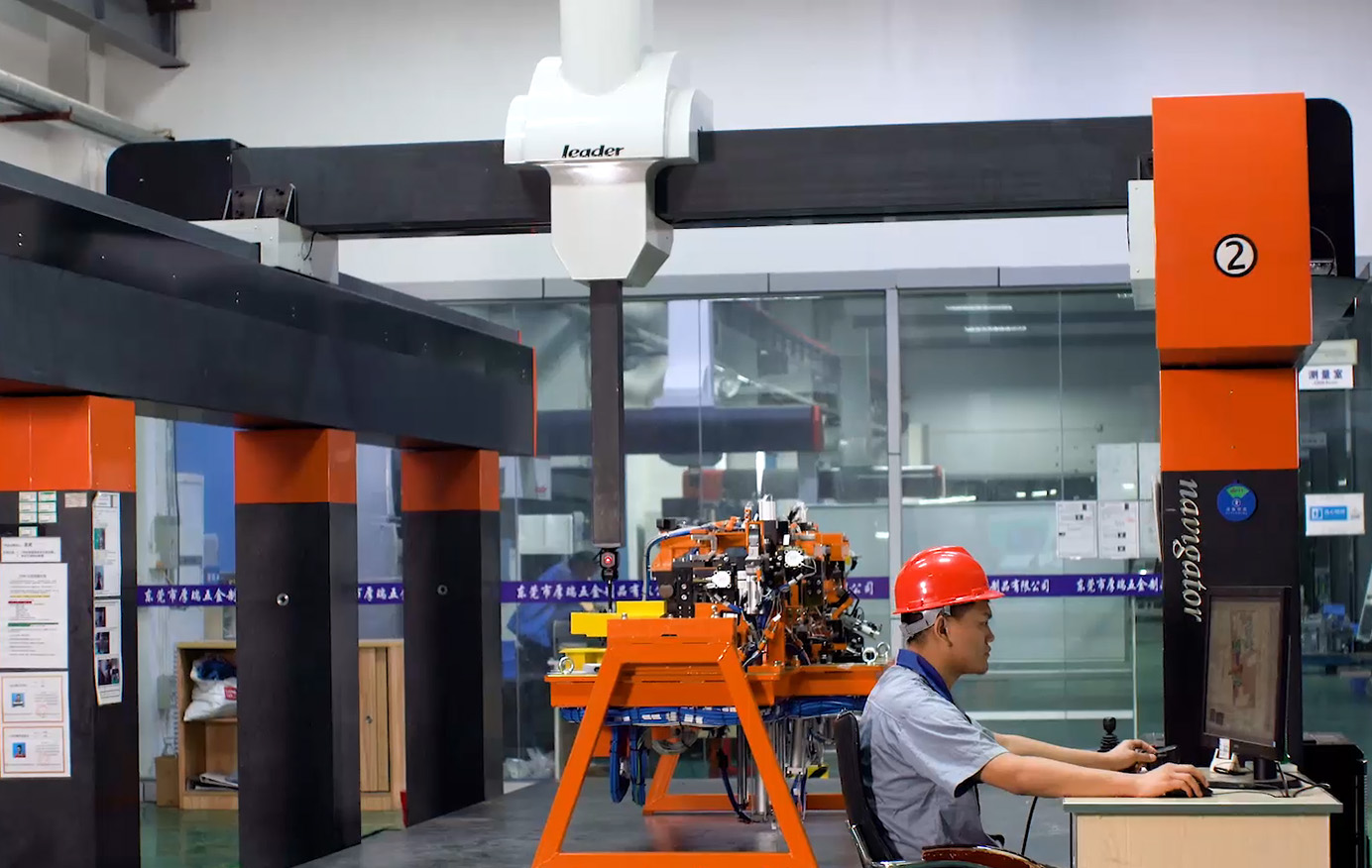

Ebe a na-atụ ihe CMM maka ịgbado ọkụ

Our ezigbo ndị ọrụ a zụrụ azụ ga-elekọta oge ọ bụla na mmemme ọ bụla anyị nwere.Anyị nwere ike ime ihe ọ bụla a chọrọ n'aka onye ahịa, iji nweta afọ ojuju kachasị na CMM.

Usoro 3 nke CMM, Mgbanwe 2/ụbọchị (hrs 10 kwa elekere Mon-Sat)

CMM, 3000*1500*1000 , Onye ndu CMM, 1200*600*600 , Onye ndu Blue-light Scanner

CMM, 500*500*400, Hexagon 2D projector, Onye Nnwale ike

.png)

.png)