automation stamping welding fixture design service emeputa

Vidiyo

Nkọwapụta

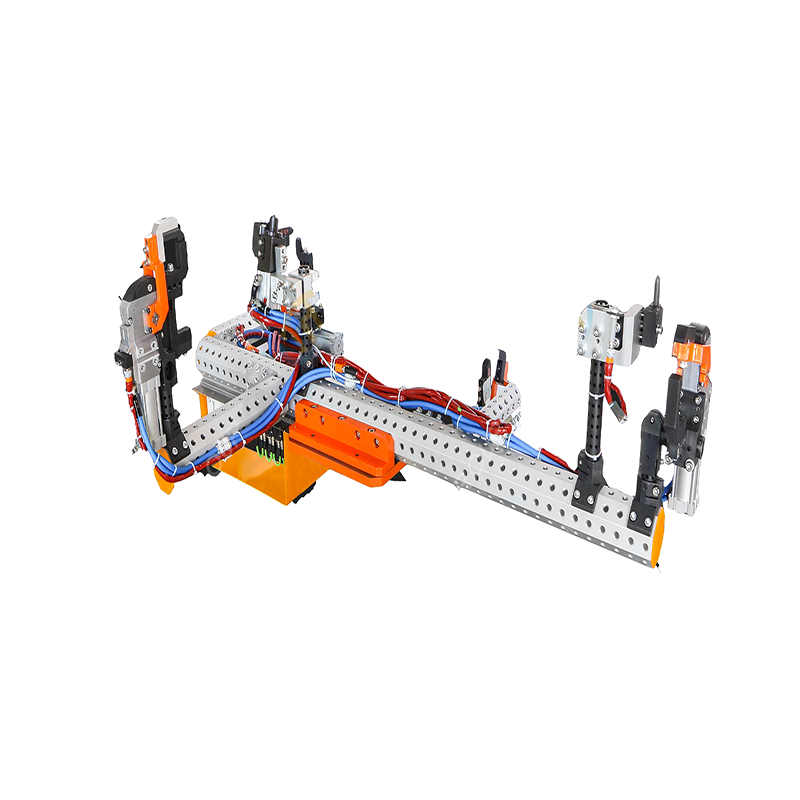

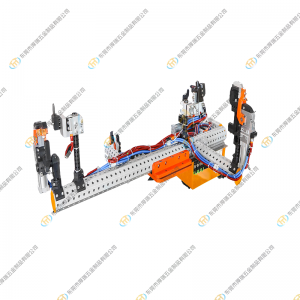

| Ụdị ịgbado ọkụ: | ARC ịgbado ọkụ |

| Ihe ndozi ịgbado ọkụ: | 6 Ntọala |

| Ndị gripers | 4 Ntọala |

| Ihe: | Ọla |

| Obodo mbupu: | Canada |

Nkọwa ngwaahịa

Okwu Mmalite zuru ezu

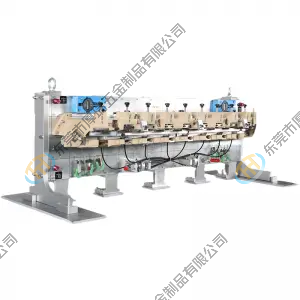

Nke a bụ ogbe nke ịgbado ọkụ nke AB mgbanaka , kpam kpam na 15 tent, anyị mere maka anyị Canada ahịa.Welding mmepụta ahịrị dị iche iche, obere ogbe na obere okirikiri bụ isi njirimara nke ụlọ ọrụ nrụpụta igwe ọgbara ọhụrụ.Ọdịdị nke njirimara a na-akwalite mmepụta nke echiche nke nkwụnye mgbanwe na mmepe nke nkà na ụzụ.Dị ka okirikiri nke ngwaahịa ọhụrụ na-adị mkpụmkpụ na mkpumkpu, otú ngwa ngwa ịgbanwee si ochie ụdị ọhụrụ ụdị na ebelata oru ngo okirikiri bụ nnyocha direction nke ọ bụla bara nnukwu uru.

Ngwunye ịgbado ọkụ na-agụnyekarị ihe nrụnye n'ala efere, mwekota kpọmkwem, usoro inyeaka, usoro njikwa ọtụtụ akụkụ.Efere ala bụ chassis nke ngwa ngwa, egbe ịgbado ọkụ na-akpaghị aka, ebuli na ihe ndị ọzọ eji eme ihe.Ọ bụ ihe bụ isi akụrụngwa nke ịgbado ọkụ fixture, na ya izi ezi na-emetụta kpọmkwem izi ezi nke n'ọnọdu usoro.Circular Seaam akpaka ịgbado ọkụ igwe bụ a ụdị eluigwe na ala akpaka ịgbado ọkụ akụrụngwa na ike mezue niile di iche iche nke okirikiri na annular welds.Enwere ike iji ya mee ihe maka carbon steel, obere alloy steel, igwe anaghị agba nchara, aluminom na alloy ya na ihe ndị ọzọ nke ịgbado ọkụ dị elu, ma nwee ike ịhọrọ ịgbado ọkụ argon arc (waya ma ọ bụ na ọ bụghị waya), ịgbado ọkụ electrode gas ịgbado ọkụ, ịgbado ọkụ plasma na ike ịgbado ọkụ ndị ọzọ. na-etolite a mgbanaka onuete akpaka ịgbado ọkụ system.It nwere ike ọtụtụ-eji na ịgbado ọkụ nke hydraulic cylinder, ụgbọ ala direction frame, mbanye aro, gas nchekwa cylinder, chemical na ọgwụ containers, liquefied gas tankị, ọkụ ọgụ ngwá, rollers na mmiri mmiri nchekwa cylinder. maka Ngwuputa na ahịrị mmepụta, wdg.

Usoro ọrụ

1. Anatara usoro ịzụrụ ihe---->2. Nhazi---->3. Na-akwado ihe osise / ngwọta---->4. Kwadebe ihe ndị ahụ---->5. CNC---->6. CMM---->6. Ịgbakọta---->7. CMM-> 8. Nyocha---->9. (Nlele akụkụ nke atọ ma ọ bụrụ na ọ dị mkpa)---->10. (n'ime/onye ahịa na saịtị)---->11. Nkwakọ ngwaahịa (igbe osisi)---->12. Nnyefe

Nlekere nrụpụta

1. Ọdịda nke efere isi 0.05/1000

2. Ọkpụrụkpụ nke Plate Base ± 0.05mm

3. Ebe Datum ± 0.02mm

4. Ihe dị n'elu ± 0.1mm

5. Ntụnye nlele na oghere ± 0.05mm

-300x3001.png)

.png)

.png)